"In today's quickly developing manufacturing landscape, the demand for environment-friendly packaging remedies has gotten substantial energy, radiating a spotlight on innovative machinery such as the egg tray making machine, egg carton making machine, and pulp molding machines. These machines are largely developed to produce different kinds of molded pulp items, which are not only biodegradable yet additionally extremely efficient in protecting fragile products like eggs throughout transportation. The egg tray making machine stands out for its capability to transform recycled paper and other eco-friendly materials into strong trays that can effortlessly fit eggs of various sizes. By using a pulp molding machine, makers can ensure a sustainable manufacturing process that benefits the setting while meeting the boosting customer demand for eco-conscious packaging choices.

Egg tray devices operate by using a mix of water, paper pulp, and warmth to mold and mildew and form the trays successfully. When the raw products are blended into a pulp, the machine develops them into the desired shapes and afterwards dries them, ensuring they are all set for usage. This procedure is not just reliable however likewise advertises the recycling of paper waste, adding to a round economic climate. Makers utilizing egg tray making devices can produce thousands of trays daily, relying on the machine's capability, making it a profitable financial investment for services in the poultry field. Moreover, these devices are frequently equipped with innovative technology that boosts production speed, lowers labor costs, and elevates overall performance.

The versatility of egg carton machinery is likewise notable as it can be adjusted for numerous products beyond simply egg trays. As an example, egg box making makers can be changed to create packaging for other breakable items, dealing with different industries such as consumer electronics and pharmaceuticals. This versatility makes pulp molding makers exceptionally useful financial investments for manufacturers looking to expand their item offerings. The egg carton making machine, in certain, can generate boxes made to hold numerous eggs, ensuring they remain secure throughout transportation and storage. The molded pulp equipment is designed for flexibility, permitting producers to produce customized designs that meet specific packaging demands.

The egg tray making machine and egg carton equipments are at the center of this change, providing sustainable solutions that minimize dependence on non-biodegradable products. Pulp molding equipment advertises the usage of recycled products while making certain premium manufacturing requirements, making these makers a sign of hope in the fight against plastic waste.

Furthermore, the worldwide promote greener company practices has led to increased investment in molded pulp machinery. Various manufacturers are stressing the value of energy-efficient equipment that minimizes carbon impacts while creating quality product packaging products. For clients interested in favoring lasting practices, deciding for a paper pulp molding machine assists reinforce their dedication to eco-friendly procedures. As a result, industries are observing a surge in demand for packaging remedies that line up with eco-conscious consumer worths, effectively improving market dynamics.

The flexibility of molded pulp devices extends to numerous various other items, including paper covers and mugs. The price of paper lid making devices varies depending on their capacities and functions, yet the investment often pays off due to set you back savings associated with reduced material expenditures and waste manufacturing.

Purchasing sophisticated machinery, such as the paper cup lid machine, can offer suppliers considerable advantages by enhancing production procedures and improving item high quality. These machines are created not just to produce covers that fit various cup dimensions but additionally to maintain uniformity in production, therefore minimizing errors. The assimilation of contemporary innovation into the layout of paper molding devices has paved the way for advancements that improve effectiveness throughout the manufacturing cycle.

In enhancement to sustainability, making use of paper-based packaging choices offers itself to enhanced branding chances. Personalized designs can be quickly created making use of egg carton machinery and mold equipment, enabling firms to develop visually attractive product packaging that talks to their brand name identity. This is vital in a competitive market, where product discussion can significantly influence customer purchasing decisions. By investing in pulp molding machinery, services can craft appealing and special product packaging that reverberates with eco-conscious customers, improving their market visibility.

The emergence of automated and semi-automated pulp molding equipments indicates a transformative change in the industry. These advancements can dramatically minimize labor expenses and minimize human mistake during production. Automation aids enhance overall manufacturing effectiveness as machines can run continuously, ensuring that services meet high-volume needs without jeopardizing quality. For suppliers looking in the direction of future-proofing their operations, spending in automation is a progression that addresses scalability and versatility to market adjustments.

When going over egg tray making equipments and related equipment is the extensive assistance supplied by suppliers, one more crucial element to take into consideration. Numerous machine vendors supply comprehensive training programs, setup solutions, and ongoing technical support to make certain that their customers efficiently incorporate this machinery right into their organization procedures. This dedication to consumer contentment better enhances the good looks more info of these equipments for those prepared to buy effective packaging production.

Furthermore, moneying possibilities and aids from governments concentrating on sustainability initiatives can aid counter the preliminary investment costs for organizations transitioning to pulp molding innovation. As laws progressively favor eco-friendly techniques, business that welcome these modifications early will likely reap the advantages of a more desirable operational landscape. In addition, the growing varieties of conscious customers may thrust services that use sustainable techniques to a competitive side, enhancing their market setting and productivity.

In recap, the demand for lasting packaging remedies has introduced a brand-new era for machinery like the egg tray making machine and the egg carton making machine. These advancements not just promote environmental duty but also use performance and potential success for services. The pulp molding machinery sector, featuring flexible makers that accommodate greater than just eggs, egg tray making machine supports a shift towards greener production techniques, increasing possibilities in packaging services. Automated equipment improves manufacturing, minimizing labor prices while boosting high quality, therefore interesting manufacturers pursuing operational excellence. As the concentrate on minimizing plastic waste increases, the importance of molded pulp equipment proceeds to expand, developing its vital function in providing sustainable packaging solutions throughout numerous sectors. Accepting these innovations can open doors for businesses, permitting them to straighten with environment-friendly consumer trends while enhancing their devotion to sustainability."

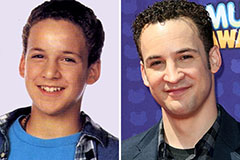

Ben Savage Then & Now!

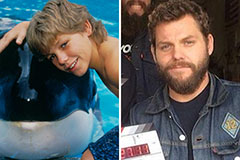

Ben Savage Then & Now! Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Mason Gamble Then & Now!

Mason Gamble Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!